Espey WD100

Espey WD100

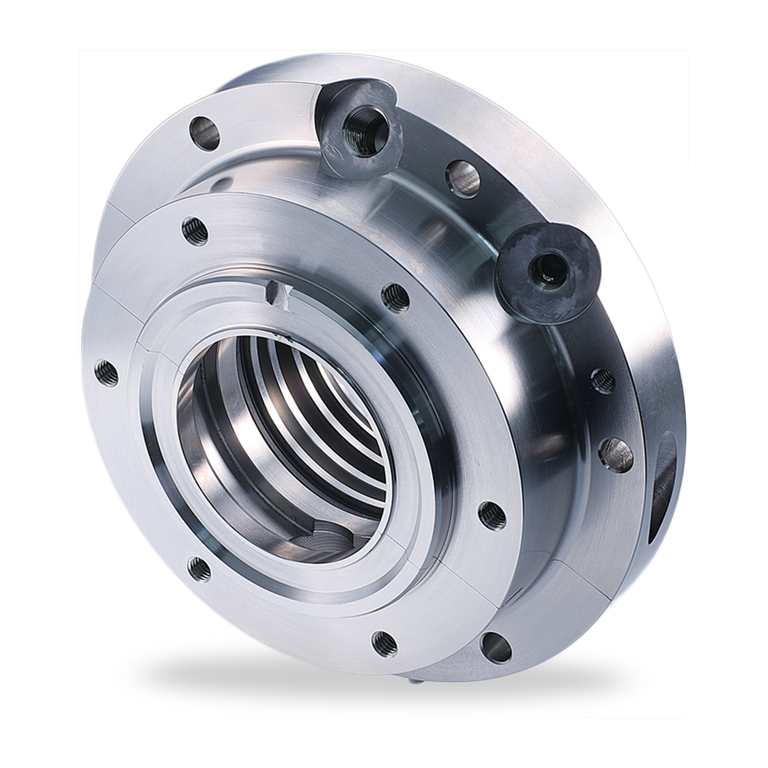

| Item | Description |

| 1 | Flat seal |

| 2 | Housing, 2-piece |

| 3 | Seal ring |

| 4 | Tension spring |

| 5 | Detent |

Espey WD100

Features

- Split housing design

- Multi-part seal rings, radially cut

- Very small operation gap – low leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- No sealing components mounted on the shaft and hence no additional shaft vibrations

- Seal rings running contact-free – sliding faces and machine consume no additional power

Advantages

- Easy installation by split housing design (shaft removal not required)

- Long-term operation time

- Maintainability

- Segmented seal rings for easy replacement

Materials

Seal ring: Carbon, PTFE compound

Housing: 1.4021, 1.4571, Hastelloy®, Titanium, Inconel®, others

Tension spring/detent: 1.4571, Hastelloy®, Titanium, Inconel®

Housing: 1.4021, 1.4571, Hastelloy®, Titanium, Inconel®, others

Tension spring/detent: 1.4571, Hastelloy®, Titanium, Inconel®

Standards and approvals

- FDA

Recommended applications

- Chemical industry

- Petrochemical industry

- Food processing industry

- Metal production and processing

- Medium-sized and large fans/blowers

- Mixers, agitators, mills, dryers

- Waste incineration and removal

- Clean gases*

- Water

* Not applicable for toxic, solids containing gasesand exhaust gas.

Product variants

Espey WD100-2 with 2 seal rings

Espey WD100-3 with 3 seal rings

Espey WD100-4 with 4 seal rings

Similar products

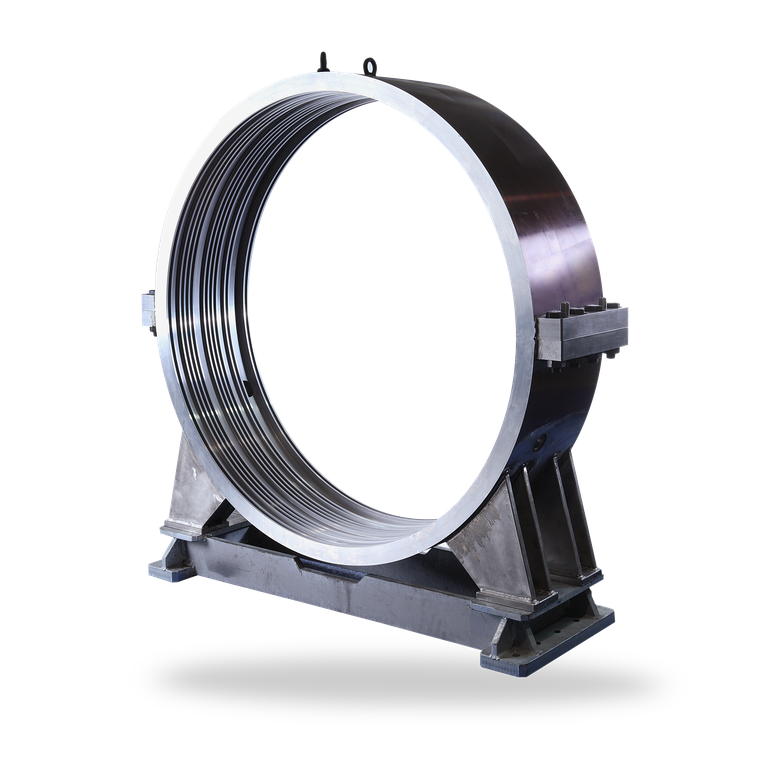

Espey Magna500+ the large seal for diameters from 500 mm

- Split housing design

- Segmented and self-adjusting seal rings

- Virtually maintenance- and wearfree

- Dry-running

- Suitable for horizontal and vertical use

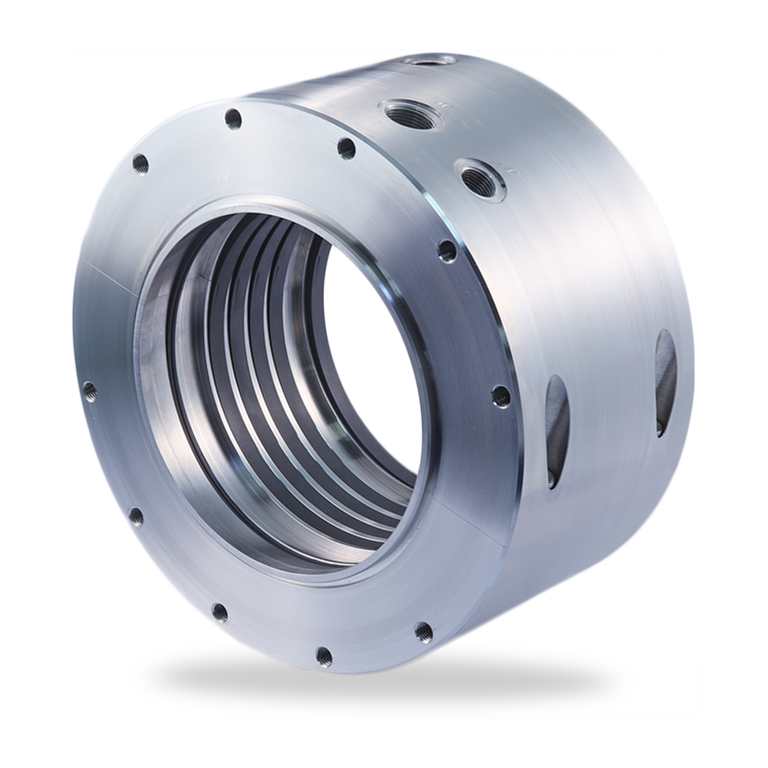

Espey WD200

- Split housing design

- Multi-part seal rings, radially cut

- Very small operation gap - low leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- No sealing components mounted on the shaft and hence no additional shaft vibrations

- Seal rings running contact-free - sliding faces and machine consume no additional power

Espey WD200/500

- Multi-part seal rings, radially cut on process side, overlapped mortised with gas tight joints on atmosphere side (adjusting)

- Split housing design

- Lowest possible operation gap - lowest leakage

- Dry running

- Self-adjusting seal rings

- Seal rings bear radial shaft movements

- Compensates axial shaft movements

- Short axial installation length

- No sealing components mounted on the shaft and hence no additional shaft vibrations